My friend, do you still remember? One of consideration in selection of relief valve type is built up back pressure. In this article I will explain you how to calculate the built up back pressure. Oh, do you still remember what is built up back pressure? Is it a constant or variable?

Built up back pressure is pressure at outlet PSV in open mode, a variable back pressure since it is depend on the relieving flow. Read my previous post about back pressure for more detail in built up and superimposed back pressure

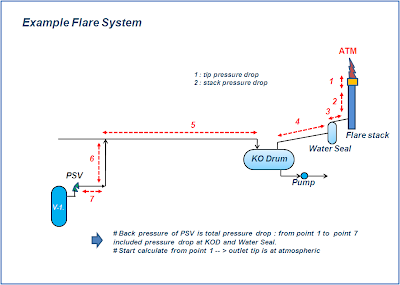

In this explanation I use a general flare system which the disposal is discharged to atmosphere via flare stack. Let imagine, when relief valve open, relieving fluid flow thru Tail Pipe –Sub Header – Main Header-Flare Drum-Seal Water Drum – Flare Stack – Flare Tip and finally discharged to atmosphere at certain height ( for safe disposal purpose)

The Built up back pressure can be calculated by count up total pressure drop at the pipe, drum, stack and tip. Start calculation from the pressure drop at the tip, then at stack until tail pipe of the relief valve. The built up back pressure is pressure that exist at outlet relief valve ( that is same as with total pressure drop from the tail pipe to the flare tip)

For more clear, see this picture below

To calculate the back pressure of the PSV, determine the pressure drop at tip, stack, Water Seal, KOD and pressure drop along the pipe from point 2 to point 7. Since the pressure at outlet tip is atmospheric pressure condition, we can calculate the pressure at outlet PSV, which is a total pressure drop along the system from point 1 to point 7.

The basis back pressure calculation is rated flow. Rated flow is flow rate based on actual orifice area of PSV. My friend, once the back pressure is calculated, then we can determine the PSV type. For built up back pressure less than 10% of PSV’s set pressure, a conventional type can be used. Balance below type can be used for back pressure up to 30%, and pilot type shall be used for higher back pressure. Note shall be made, even though the selection of PSV type is based on the back pressure consideration, it is not the only consideration in PSV selection

After the back pressure calculated, we can also check the fluid condition due to decreasing pressure from inlet PSV (relieving pressure) to outlet PSV (back pressure) using HYSYS simulator. Is hydrate formed there? is the icing occurred? And for liquid phase, is the liquid will be flashed?

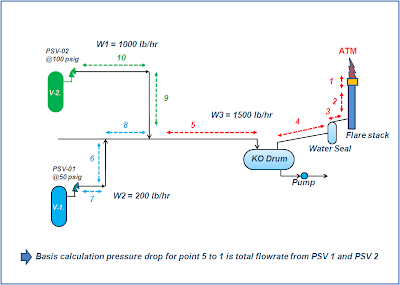

The back pressure calculation is so simple, isn’t? How about if there is any PSV open simultaneously? The difference is only the combined flowrate from others PSV shall be considered in pressure drop calculation. Hopefully this picture help you more understand with the concept of back pressure calculation.

<< correction : W3 at above picture shall be 1200 lb/hr instead of 1500lb/hr>>

See the picture above. I will explain you why the calculation of built up back pressure is very important not only for PSV design but also for flare system design. Let imagine;

- PSV 01 is set at 50 psig with relieving flow of 200 lb/hr.

- PSV 02 is set at 100 psig with relieving flow of 1000 lb/hr.

In case the two PSV open simultaneously, what do you think what happen with the PSV 01 if the back pressure of PSV 02 is more than 50 psig? Of course the PSV 01 cannot open properly

What is the solution? Hmm,, look at this picture, it will show you a better configuration of flare header system to avoid that condition

<< correction : W3 at above picture shall be 1200 lb/hr instead of 1500lb/hr>>

The other options are increase the flare header size or provide 2 flare header for high pressure and and low pressure separately.

The above sample is a very simple case. Sometimes, for instance in power failure case, there is many PSV will open at the same time. The back pressure for each PSV shall be checked to ensure each PSV can properly operated. The back pressure profile of each PSV can be used to determine the configuration of the flare system

My friend, that’s all, I can share to you. Hopefully, this topic reminds us that the back pressure is something very important to be considered both in PSV and flare system design

Thank you for your attention.

No comments:

Post a Comment