My friend, In

this posting we will discuss about the pump recycle systems. The pump shall be protected from minimum flow, due to the following reasons;

1. Thermal consideration which has effect to the pump efficiency (The efficiency will decrease significantly at low flow)

2. At low flow, Internal recirculation will be occurred

3. Increase load impeller (both axial and radial)

4. liquid containing a large amount of abrasive particles must flow continuously through the pump. at low flow, the particles can circulate inside the pump and erode the impeller.

The three types of pump recycle systems which are generally applied are ;

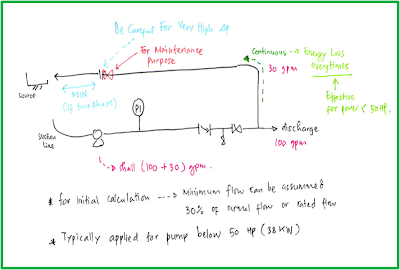

1. Continuous recycle system --> use Orifice

2. Control loop system and --> use Control Valve

3. Automatic recycle system. --> use ARC

My friend, The followings are short guidance to apply those types.

1. ORIFICE

- This system will provide continuous recycle flow whenever pump is running, regardless of the process demand.

- Typically applied for pump below 50 hp (38kW), or small capacity.

- Don’t forget, you must consider the additional capacity of the pump (the capacity is included recycle flow)

- For initial estimation, 30% of rated flow can be used as recycle flow basis.

- Take care for high pressure drop condition, is there any flashing? Two phase? Or vibration? If two phases is occurred, the orifice should be located at the end of the recycle line.

2. CONTROL VALVE

- When the minimum flow is reached, the valve start to open. The flowmeter shall be located at pump discharge side (installing at suction side will decrease the suction pressure, decrease NPSHa )

- The flow meter should be located before(upstream the) recycle line connection.

- Be careful with high pressure drop, control valve may be noise and vibration (an orifice in series with the control valve may be required)p

3. AUTOMATIC RECIRCULATION

- This type is the spring loaded, combined recycle and check valve

- The spring loaded is set at a pressure correspond to minimum flow (based on pump curve) where the recycle starts to open.

- Check this link for the detail how the ARC valve work.

- No need additional check valve in the discharge system. The ARC provides back flow protection.

- Take care with pump with high discharge pressure ( while low pressure source) . The orifice may be required at the recycle line to avoid very big change of momentum

General Guide.

- Recycle line should be routed back to the source (tank or vessel) NOT to pump suction. Bubble of two phases can be formed during pressure reduction by orifice or control valve. It may be introduced into the pump.

- Routing to suction line may causes excessive temperature build up in a very short time.

- For 2 x 100% operation, the recycle line can be connected at combined line.

- For 2 x 50 % operation, each pump shall have its own recycle system.

-

Generally,

the recycle system is not shown in the PFD. There are two specific pumps when a

recycle system should be included in the PFD. These are the BFW pump and pump

with the high head or capacity. (discharge pressure > 1000 psig)

That's all I can share this time.

Hopefully this is useful for you..

Wait ..wait..I have a question for you.

Here my simple question.

Let say, 100 gpm liquid shall be transferred via pump to a tank. The recycle is continuous of 30 gpm use orifice.

How you state

the pump capacity in the process datasheet?

A. Normal = 100 gpm , Rated = 100 +30 = 130 gpm

B. Normal = 130 gpm, Rated = 130 x 1.1 = 143 gpm

C. Normal = 100 gpm, Rated = 1.1 x 100 + 30 = 140 gpm

A. Normal = 100 gpm , Rated = 100 +30 = 130 gpm

B. Normal = 130 gpm, Rated = 130 x 1.1 = 143 gpm

C. Normal = 100 gpm, Rated = 1.1 x 100 + 30 = 140 gpm

hhmm,,,can you explain WHY ? it is simple, isn't ? :D

No comments:

Post a Comment