My friend, how are you today, ? I hope this weekend give us the best of everything ; find some good experiences, new spirit, and (may be) new planning for the better future, etc.

My friends, Let me share a simple material regarding the discharge pump system, but in this posting, I will only focus on centrifugal pump type.

The followings are the points to be considered when we design centrifugal pump discharge system. Hope this article help you in checking P&ID..

1. Provide block valve for isolate the discharge side

The block valve or isolation valve will be used for :

- Priming and regulating flow

- Isolating the pump for inspection and maintenance

The type of block valve can be either gate valve, ball valve or butterfly valve type depends on the piping specification.

2. Provide a pressure gauge (PG or PI) to verify the discharge pressure

The pressure gauge should be located close to the outlet of the pump. It will help you diagnose pump system problem. The pump head can be determined based on the pressure gauge at suction and discharge pump. But the static head shall be counted for correction.

3. Provide check valve to protect the pump

The check valve will protect the pump in the event of sudden stoppage that cause reversal flow in an upset condition. Without check valve, pump may running in reverse direction, pump shafts have been broken this way.

The following picture is a sample of discharge pump system.

An example of typical system which potential cause back flow or reverse flow.

My friends, the following is just an example, of course it is not a real condition . I want to explain this as simple as possible. hopefully, you can imagine the back flow or water hammer phenomenon more easily.

The pump deliver liquid through high elevation to the destination which is lower than the highest point. The liquid will flow back to the pump when upset condition or sudden pump stop.

In the system above, when start up water hammer can be occurred. It is suggestion to install manual valve that are controlled to open gradually.

Control valve in the suction side cause pump work in unstable condition, also will cause more pressure drop to suction system, and finally decrease the NPSH.

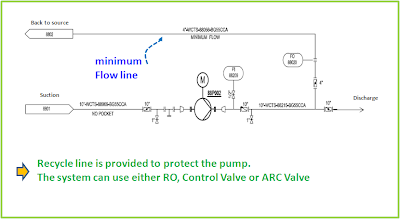

5. Provide minimum flow to protect the pump

Centrifugal pumps should not be used at a low flowrate less than a certain percentage of BEP ( Best Efficiency Point). Generally the minimum flowrate required for centrifugal pump may be in range 50%-70% of BEP.

Hopefully we can discuss more deep about the minimum flow of centrifugal pump in other time. the following is just an example.

The system can use RO or control valve or automatic recirculation valve (ARC).

The rule of thumb say that the control valve system typically becomes economical above 50 hp ( 38 kW) and the RO applied for pumps below 50 hp (38 kW).

My friends, thank for reading.

I will very appreciate you if you give me comment or correction when I make any mistakes in this posting.

Hope this useful for you. .

Happy weekend,..,,

No comments:

Post a Comment